Factor of Safety

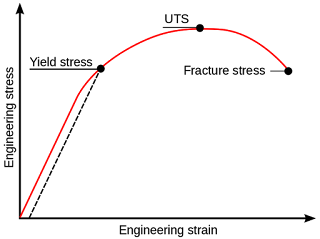

From the

stress-strain curve we note that ultimate stress is the maximum value of

stress, the material withstands before failure.

So, should we

allow the material to reach its ultimate stress value while in operation?

The answer is

No..! as we would like to keep some scope for safety, since the estimated

operation loads may be exceeded at time. Also, the ultimate stress value may be

different from that of the tested specimen.

Hence, the

actual stress is kept much below the ultimate stress limit. In fact, ideally

the stresses should be kept within the elastic limit. The upper limit up to

which the stresses are permitted is known as the permissible stress or

allowable stress or safe stress or working stress.

The ratio of

Ultimate stress to safe stress/Working Stress know as Factor of Safety. It works as a

protective shield against failure of material under stress.

The factor of

safety for a component or structural part has to the be chosen very carefully.

If chosen too small, the possibility of failure becomes dangerously large and

if chosen very large, the design can become uneconomical. Generally, the choice

of factor of safety for a component is influenced by the flowing

considerations:

Material Properties:

Material used for a component may not be

homogeneous, i.e., it may not have the same properties throughout. The

composition, strength and its dimensions may have small variations during its

manufacture. The properties are also altered when a material undergoes various

heat treatments.

Type of Loading:

A designer may keep in mind the type of

loading (static, impact, reversal, etc.) a structure is going to withstand; yet

there are possibilities of inaccuracy in his estimates. There can also be

alterations of use of a structure with time.

Number of Loading:

The actual number of loading during the

life of a component may be different from the expected loading at the time of

designing. The ultimate stress usually decreases with increase in the number of

loading. This phenomenon is known as fatigue and plays a key role in designing.

Type of Expected

Failure:

Sometimes, the collapse of a structure

may occur suddenly and there is no prior indication as in case of brittle

materials. In such cases where there is possibility of sudden failure, a higher

factor of safety has to be used then where there is possibility of pre-warning

in the form of yielding of the material.

Method of Analysis:

As all relations and analyzing methods

are based on certain assumptions, it is appropriate to include some factor of

safety for such type of assumptions and simplifications.

Maintenance:

All mechanical components and

structures require good maintenance during their lifetime. However, to consider

poor maintenance, rusting, corrosion, decay and other natural uncertainties in

future, some margin has to be included.

Few

more piping resources...

- Stress Analysis of Column Piping System - 01

- Stress Analysis of Column Piping System: PIPING &COLUMN MODELLING IN CAESAR-II

- Basics of Pipe analysis: Objectives

- Basics of Pipe analysis: Principal stresses

- Piping Stress Basic

- Piping Stress analysis

0 Comments

Please do not enter any spam link in comment box