Magnetic Particle Testing Equipment.

The following should be considered when selecting Magnetic Particle Testing

- Is Equipment for Wet or Dry method.

- Magnetization requirement.

- Demagnetization- Incorporated or separated unit?

- Amperage Required.

- Line Voltage Requirements.

- Accessories Needed or Required.

Wet Horizontal Equipment

To obtain

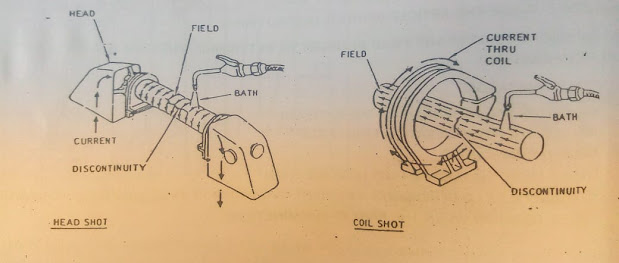

Circular Magnetization, the specimen is clamped between the Head and Tail

Stocks.

For

Longitudinal Magnetization, the coil is moved so that the area to be tested is

encircled by the coil.

A typical Wet

Horizontal Unit usually accommodates both AC and HWDC Magnetization. The Wet continuous field method has three

basic steps;

- Flow bath through nozzle and over entire surface of part.

- Stop bath flow.

- Apply current at the instant bath flow is stopped.

Dry continuous-field method

With this

method the powder is usually applied from a shaker, bulb, or blower and follows

these steps:

- Apply magnetizing current

- Blow powder particles over magnetized area.

- Blow excess powder off part.

- Shut off magnetizing current.

The powder should float to the magnetized area so the particles will be attracted to any flux leakages. The dry powder method is typically used with both mobile and portable equipment which will be discussed on the following.

Mobile Equipment

In many cases it is necessary to bring the equipment to the specimen.

|

| Typical Mobile Equipment |

The Cables

used on the above vary from 15 feet to 100 feet. Shorter cable will permit the

maximum current output.

Prods and

Cables are usually used with the mobile equipment. It often takes two technicians

to manipulate the Prods & apply the magnetic powder.

However, Longitudinal

Magnetization can be produced by wrapping the cable into a coil. It is also

possible to use a central conductor clamped between the two cables to produce

Circular Magnetization.

Typical

Mobile equipment uses the Dry Powder Method but can be use with Aerosol cans or External Tanks.

Portable Equipment

Portable Equipment is lighter and less expensive than the other types of magnetic particle testing equipment.

|

| Typical Portable Equipment |

As with

mobile equipment, the cables can be used for prods, wrapping into a coil or

connecting to a central conductor.

Portable Equipment also used the Dry Powder Method for most application.

Demagnetizing Equipment

The most

common type of Demagnetizing Equipment consists of an open coil through which

AC is flowing.

A typical unit is shows below and includes a track that will carry the part through the coil. As the part is carried away from the coil the magnetic field is reduced. The continuously AC current in the coil completes the demagnetization.

0 Comments

Please do not enter any spam link in comment box