INTRODUCTION

Because magnetization of certain metals is possible. it is possible to reveal discontinuities by using a medium (iron powder) having magnetic attraction. The medium is applied to the surface of the test object after or during induction of a magnetic field.

The sketch below shows a build up of the magnetic particle medium over the discontinuity in the magnetized part.

Magnetic particle teat is a relatively easy and simple test

method that can be applied at various stages of manufacture and processing

operation.

The objective of magnetic particle testing is to insure product reliability by providing a means of:

- Obtaining a visual image of an indication on the surface of a material.

- Disclosing the nature of discontinuities without impairing the material.

- Separating acceptable and unacceptable material in accordance with predetermined standards.

Theory of Magnetization

An object is magnetized when part or all of it magnetic domains have their north and south poles oriented as in the sketch below.

The ability of a magnet to attract or repel is concentrated at the local area called poles. The north and south poles exhibit attraction and repulsion as shown in the sketch below.

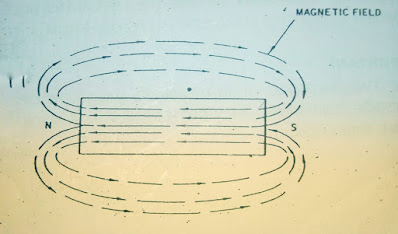

With all the magnetic domain’s lines up, the magnetic bar developed a total force equal to the sum of all the magnetic domains. These are the magnetic lines of force which form a closed loop or circuit. All the lines of force make up the magnetic field.

The force that attracts other magnetizable materials to the materials to the magnetic poles is known as magnetic flux.

Magnetic flux is made up of all the lines of force.

The horseshoe magnet will attract other magnetizable

material only where the lines of force leave or enter the magnet.

The horseshoe magnet will attract other magnetizable

material only where the lines of force leave or enter the magnet.

If a magnet is bent into a complete loop as shown below. The magnetic field is entirely within. Thus no external force.

However, a crack in the circular magnet will disrupt the flow of lines of force and create a flux leakage.

Leakage fields (flux leakage) are magnetic lines of force that leave the part and pass through air from one pole to the other of opposite polarity.Whenever the leakage field is forced out of the part, iron particles would be attracted showing an indication of a discontinuity.Even some subsurface discontinuities may be detected if the leakage field is strong enough as shown below.

VECTOR FIELD

When two magnetizing forces are imposed simultaneously in the same part. The object is not magnetized in two directions at the same time. A vector field is formed which is the resultant direction and strength of the imposed fields. This is illustrated below. Where FA is the first magnetizing force, FB is the second force, and FA+B equals the resultant magnetizing force.

Magnetic Materials

If an object is placed in a magnetic field a force is

exerted on it and it is said to become magnetized.

The intensity of magnetization depends upon the susceptibility of The material to become magnetized.

A. Diamagnetic metals: Have a small and negative susceptibility to magnetization (slightly repelled).

Copper, silver, and gold are examples of diamagnetic

materials.

B. Paramagnetic metals: Have

a small and positive susceptibility to magnetization (slightly attracted).

Magnesium, molybdenum, lithium, and tantalum are examples.

C. Ferromagnetic metals: Have a large and positive susceptibility to magnetization. They have a strong attraction and can retain their magnetization after the magnetizing field has been removed. iron, cobalt, and nickel are examples of ferromagnetic metals.

Ferromagnetic materials are the only metals commonly inspected with the magnetic particle testing method.

Magnetic Flux

The

total number of magnetic lines of force existing in a magnetic circuit is called

magnetic flux.

The lines of force in a magnetic circuit are always closed loops, therefore, a magnetic circuit are always closed loops, therefore, a magnetic circuit is. Always closed as shown below.

Flux density-or induction is usually designated in “Gauss” units and refers to the flux-per-unit area at right angles to the direction of the flux.

Right-hand rule vs Left-hand rule

To find the direction of an electrically induced magnetic field, place your thumb on the conductor in the direction of “current flow” and your fingers will then point in the direction of the lines of force. A circular magnetic field is produced in the sketch below.

The general dynamics. Handbook uses the “current flow” theory which utilizes the right-hand rule. This older convention electricity is considered to flow from + to-.

If the more commonly accepted “electron flow” theory were

used, it would be necessary to use the left-hand rule. The “electron flow”

theory considers electricity to flow from-to +.

Important

The two methods of determining the flow of electricity should not become confusing. They both result in a magnetic field flowing in the same direction.

The sketch below shows how a magnetic field is produced utilizing a coil. The field is circular around the cable but produces a longitudinal field in the specimen.

Using figure “A” below. Try the right-hand rule (current flow+ to -) to demonstrate the direction of the magnetic field with the “current flow” theory.

Also, try the left-hand rule on figure "B" below to demonstrate that the “electron flow” theory (-to+) will produce a magnetic field in the same direction.

The following properties of a metal can determine how effective the magnetic particle method will be in evaluating a part. These properties will be discussed in greater detail in the next lesson.

1.Permeability- this refers to the ease with which a

magnetic flux is established in the article being inspected.

2.Reluctance- this is the opposition of a magnetic material

to the establishment of a magnetic flux.

3. Residual magnetism- this refers to the amount of

magnetism retained after the magnetizing force is removed.

4. Retentivity- refers to the ability of the material to

retain a certain amount of residual magnetism.

5.Coercive force-refers to the reverse magnetizing force necessary to remove the residual magnetism from the part.

For example: if a piece of high carbon steel were placed in

a magnetizing field it would exhibit the following:

- It would- have low permeability because it would be hard to magnetize.

- It would be highly reluctant to accept magnetic flux because of the high carbon content.

- It would have a high residual magnetic field. The high carbon steel is reluctant to accept a magnetic flux but is also reluctant to give it up once it has been accepted.

- It would be highly retentive of the magnetic field that it has accepted.

- It would take a high coercive force to remove the residual magnetism from the high carbon steel part.

0 Comments

Please do not enter any spam link in comment box