Introduction:

In our last article, Magnetic Particle Testing-IV; we have discuses about Current Field Distribution Around the Conductor. In this article we are going to learn about the Current requirement for magnetization for Magnetic Particle Testing.

Current Requirements (Circular Magnetization)

The amount of current will vary with the shape and permeability or the material being tested. At test specimen with a typical indication is a good method to assure that only enough current is used to show the indication.

- Too much current will burn the part or may cause heavy accumulations of iron particles.

- Too little current may not provide enough flux leakage to attract the iron particles.

The following rule is used to determine the current needed:

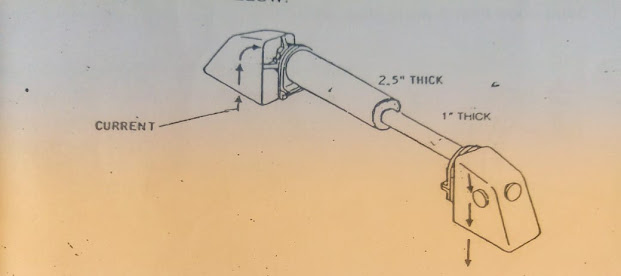

800-1000 amperes per inch of article thickness or diameter.to use this rule on article of greater thickness, just multiply the 800 and 1000 by the number of inches of article thickness. What amperage would be used on the following part?

Steel bar 10

X 3 X 2 inches thick

Answer: 1600

to 2000 amps

What amperage range is required to circularly magnetize the bar shown the head shot below?

Answer: 800 to 1000 for first shot

2000 to 2500 for second shot

The rule of using 800-1000 amperes per inch of thickness also applies to circular magnetization with a central conductor. Article thickness is taken from the outside diameter of the article.

what would the ampere ranges be for the three parts shown on the central conductor below?

Answer: 800 to 1000 for 1 inch Nut

1600 to 2000 for 2 inch Ring

2400 to 3000 for 3 inch Spacer

Current requirements (longitudinal magnetization)

When a coil is used to produce longitudinal magnetization, the effective filed it creates is determined by the product of the number of amperes and the number of turns in the coil. for example, a current of 800 amperes through a five-turn coil creates a magnetizing force of 4000 amperes turns.

The amount of current needed for longitudinal magnetization with a coil is controlled by the formula:

Where,

I=Current in amperes

N=Number of turns in coil

L=Length of article

D=Diameter or thickness of article

The figure 45,000 is a constant for all computations. L\D is the length to diameter or thickness, ratio of the pat in is the ampere- turns.

When the number of ampere-turns is found using the above formula. The next step is to divide the Ampere-Turn by the number of turns is the coil. This will determine the magnetizing current needed most coils typically have three to five turns.

What magnetizing current would be need for a part 16 inches long

with a diameter of 2 inches, using a five- turn coil?

Answer: 1125 Amperes

Following Assumption are made, while using the formula

- An article greater than 18 inches requires more than one coil shot.

- The cross section of the article is not greater than one-tenth the area of the coil opening.

- The article has an L/D ratio of between 2 and 15.

- The article is placed against the inside wall of the coil, and not in the center where the flux density is zero.

Prod magnetization

Prods are current- carrying conductors (usually copper) which are used to magnetize localized areas as shown below.

Caution: the use of prods may be restricted for some applications due to the possibility of burns at the point of contact.

Prod

magnetization creates a circular magnetic field in the part. In the sketch

above can you use the left- hand rule to determine if the current is flowing

from A to B or from B to A?

A guideline

for determining how any given testing problem is shown below.

When Half-Wave direct current (HWDC) is used, the field strength per ampere is about the same as with Direct Current (DC) at typical prod spacing (6 to 8 inches).

However, since HWDC consumes less power and produces lower heating effects at the prod contact points, it is often recommended. HWDC also produces better powder mobility than DC.

The prods

should be placed on the part so that the resultant circular field is at 90

degrees to the suspected discontinuities.

0 Comments

Please do not enter any spam link in comment box