Introduction

In our last article, Magnetic Particle Testing -III; we have discuses about Hysteresis Loop and it behavioral relation with Alternating Current, Direct Current and Half-Wave Alternating Current. In this article we are going to learn about Magnetic Field Distribution around the testing material. This help to understand the method of magnetization and Demagnetization as per the requirement.

Direct current filed distribution in Solid Conductor

A. Solid nonmagnetic conductor

When direct current is passed directly through a solid nonmagnetic conductor, such as a copper bar, the following can be observed:

- The magnetic field strength varies from zero at the center to a maximum at the surface.

- The field strength outside the conductor diminishes with the distance from the center conductor ‘s center (e.g. the field at two times the radius from the center is half the field at the surface).

B. Solid magnetic conductor

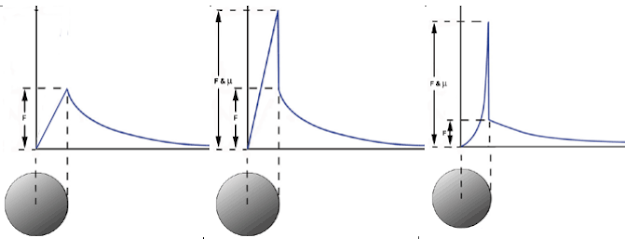

Distribution of a direct current magnetic field within a magnetic article can be illustrated graphically as shown below.

- The flux density increases evenly from zero until it reaches peak strength at the surface.

- Because of the permeability of steel, the field strength is greater within a magnetic conductor as compared to a nonmagnetic conductor.

- The flux density drops rapidly just outside the surface of the steel bar.

- The field strength outside a solid conductor is the same with either a magnetic or nonmagnetic conductor.

Hollow conductor

A. Hollow magnetic conductor

Permeability is again a factor in determining field strength. If the outer diameter and current flow are identical when comparing a solid and hollow conductor, the filed strength will be the same.

B. Hollow nonmagnetic conductor

In both magnetic and nonmagnetic hollow conductors, the filed strength is zero at the inner surface and increases to maximum at the outer surface.

As with both solid and hollow, and both magnetic and nonmagnetic, the field strength outside the conductor diminishes with the distance from the central conductor’s center. However,

The difference between the permeability of magnetic and nonmagnetic materials affects the field strength within the conductor.

Because of the low permeability of a nonmagnetic conductor, the field strength is relatively low. as shown below, direct current flowing through a central conductor will produce a maximum field on the inside surface of the tube being inspected.

Since the magnetizing force is from the field external to the central conductor, it is obvious (by comparing previous sketches) that either a magnetic or nonmagnetic bar could used for a central conductor.

However,material such as copper is often recommended as a central conductor because there is less heat build-up due to better conductivity.

Alternating current filed distribution

Up to this point, all filed distributions have assumed the use of Direct Current (DC)

Alternating Current (AC) tends to flow near the surface of a conductor. This phenomenon is known as “skin effect.” It is shown below that AC provides a concentrated flux density near the surface which provides for good detection of surface discontinuities.

- It is also shown above that DC provides the best conditions for locating subsurface discontinuities because of the distribution of the flux density.

- The field strength outside the conductor is comparable for both AC and DC.

- As with DC both conductivity and permeability affect the field strength and distribution.

Sensitivity of methods

It is well established that AC method is best suited for finding

surface defects.

However, the chart below illustrates the ability of various currents using both wet and dry magnetic particles in locating subsurface discontinuities.

0 Comments

Please do not enter any spam link in comment box