1. Introduction

Refrigeration deals with cooling of bodies or fluids to temperatures lower than those of surroundings. This involves absorption of heat at a lower temperature and rejection to higher temperature of the surroundings.

|

| Relation between refrigeration and air conditioning |

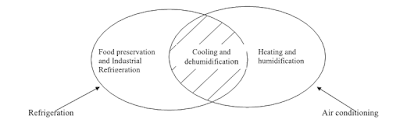

In olden days,the main purpose of refrigeration was to produce ice, which was used for cooling beverages, food preservation and refrigerated transport etc. Now-a-days refrigeration and air conditioning find so many applications that they have become very essential for mankind, and without refrigeration and air conditioning the basic fabric of the society will be adversely affected. Refrigeration and air conditioning are generally treated in a single subject due to the fact that one of the most important applications of refrigeration is in cooling and dehumidification as required for summer air conditioning. Of course, refrigeration is required for many applications other than air conditioning, and air conditioning also involves processes other than cooling and dehumidification. Figure shows the relation between refrigeration and air conditioning in a pictorial form. The temperature range of interest in refrigeration extends down to about –100oC. At lower temperatures cryogenic systems are more economical. Now-a-days refrigeration has become an essential part of food chain- from post harvest heat removal to processing, distribution and storage. Refrigeration has become essential for many chemical and processing industries to improve the standard, quality, precision and efficiency of many manufacturing processes. Ever-new applications of refrigeration arise all the time. Some special applications require small capacities but are technically intriguing and challenging.

As mentioned before, air-conditioning is one of the major applications of refrigeration. Air-conditioning has made the living conditions more comfortable, hygienic and healthy in offices, work places and homes. As mentioned in Lesson 1, air-conditioning involves control of temperature, humidity, cleanliness of air and its distribution to meet the comfort requirements of human beings and/or some industrial requirements. Air-conditioning involves cooling and dehumidification in summer months; this is essentially done by refrigeration. It also involves heating and humidification in cold climates, which is conventionally done by a boiler unless a heat pump is used.

The major applications of refrigeration can be grouped into following four major

equally important areas.

1. Food processing, preservation and distribution

2. Chemical and process industries

3. Special Applications

4. Comfort air-conditioning

2. Application of refrigeration in Food processing, preservation and distribution:

2.1. Storage of Raw Fruits and Vegetables:

It is well-known that some bacteria are responsible for degradation of food, and enzymatic processing cause ripening of the fruits and vegetables. The growth of bacteria and the rate of enzymatic processes are reduced at low temperature. This helps in reducing the spoilage and improving the shelf life of the food. Table 2.1 shows useful storage life of some plant and animal tissues at various temperatures. It can be seen that the storage temperature affects the useful storage life significantly. In general the storage life of most of the food products depends upon water activity, which essentially depends upon the presence of water in liquid form in the food product and its temperature. Hence, it is possible to preserve various food products for much longer periods under frozen conditions.

In case of fruits and vegetables, the use of refrigeration starts right after harvesting to remove the post-harvest heat, transport in refrigerated transport to the cold storage or the processing plant. A part of it may be stored in cold storage to maintain its sensory qualities and a part may be distributed to retail shops, where again refrigeration is used for short time storage. Depending upon the size, the required capacity of refrigeration plants for cold storages can be very high. Ammonia is one of the common refrigerants used in cold storages. Figure 3.2 shows the photograph of ammonia based refrigerant plant for a cold storage. Figure 3.3 shows the photograph of a typical cold storage.Household refrigerator is the user end of cold chain for short time storage.

|

| Ammonia based refrigeration plant for a large cold storage |

The cold chain has proved to be very effective in reducing spoilage of food and in food preservation. It is estimated that in India, the post-harvest loss due to inadequate cold storage facilities is high as 30 percent of the total output. The quality of remaining 70 percent is also affectedly inadequate cold chain facilities. This shows the importance of proper refrigeration facilities in view of the growing food needs of the ever-growing population. Refrigeration helps in retaining the sensory, nutritional and eating qualities of the food. The excess crop of fruits and vegetables can be stored for use during peak demands and off-season; and transported to remote locations by refrigerated transport. In India, storage of potatoes and apples in large scale and some other fruits and vegetables in small scale and frozen storage of peas, beans, cabbage, carrots etc. has improved the standard of living. In general, the shelf life of most of the fruits and vegetables increases by storage at temperatures between 0 to 10oC. Table 3.2 shows the typical storage conditions for some fruits and vegetables as recommended by ASHRAE. Nuts, dried fruits and pulses that are prone to bacterial deterioration can also be stored for long periods by this method. The above mentioned fruits, vegetables etc, can be stored in raw state. Some highly perishable items require initial processing before storage. The fast and busy modern day life demands ready-to-eat frozen or refrigerated food packages to eliminate the preparation and cooking time. These items are becoming very popular and these require refrigeration plants.

|

| Photograph of a typical cold storage |

2.2. Fish:

Icing of fish according to ASHRAE Handbook on Applications, started way back in 1938. In India, iced fish is still transported by rail and road, and retail stores store it for short periods by this method. Freezing of fish aboard the ship right after catch results in better quality than freezing it after the ship docks. In some ships, it is frozen along with seawater since it takes months before the ships return to dock. Long-term preservation of fish requires cleaning, processing and freezing.

|

| Recommended storage conditions for fruits and vegetables |

2.3. Meat and poultry:

These items also require refrigeration right after slaughter during processing, packaging. Short-term storage is done at 0oC. Long-term storage requires freezing and storage at -25oC.

2.4. Dairy Products:

The important dairy products are milk, butter, buttermilk and ice cream. To maintain good quality, the milk is cooled in bulk milk coolers immediately after being taken from cow. Bulk milk cooler is a large refrigerated tank that cools it between 10 to 15oC. Then it is transported to dairy farms, where it is pasteurized. Pasteurization involves heating it to 73oC and holding it at this temperature for 20 seconds. Thereafter, it is cooled to 3 to 4oC. The dairies have to have a very large cooling capacity, since a large quantity of milk has to be immediately cooled after arrival. During the lean period, the refrigeration plants of dairies are used to produce ice that is used during peak periods to provide cooling by melting. This reduces the required peak capacity of the refrigeration plant.

Ice cream manufacture requires pasteurization, thorough mixing, emulsification and stabilization and subsequently cooling to 4 to 5oC. Then it is cooled to temperature of about – 5

oC in a freezer where it stiffens but still remains in liquid state. It is packaged and hardened at –30 to –25oC until it becomes solid; and then it is stored at same temperature.

Buttermilk, curd and cottage cheese are stored at 4 to 10oC for increase of shelf life. Use of refrigeration during manufacture of these items also increases their shelf life. There are manyvarieties of cheese available these days. Adding cheese starter like lactic acid and several substances to the milk makes all of these.

2.5. Beverages:

Production of beer, wine and concentrated fruit juices require refrigeration. The taste of many drinks can be improved by serving them cold or by adding ice to them. This has been one of the favorite past time of aristocracy in all the countries. Natural or man-made ice for this purpose has been made available since a very long time. Fruit juice concentrates have been very popular because of low cost, good taste and nutritional qualities. Juices can be preserved for a longer period of time than the fruits. Also, fruit juice concentrates when frozen can be more easily shipped and transported by road. Orange and other citrus juices, apple juice, grape juice and pineapple juice are very popular.To preserve the taste and flavor of juice, the water is driven out of it by boiling it at low temperature under reduced pressure. The concentrate is frozen and transported at –20oC.

Brewing and wine making requires fermentation reaction at controlled temperature, for example lager-type of beer requires 8 to12oC while wine requires 27-30oC. Fermentation is an exothermic process; hence heat has to be rejected at controlled temperature.

2.6. Candy:

Use of chocolate in candy or its coating with chocolate requires setting at 5-10oC otherwise it becomes sticky. Further, it is recommended that it be stored at low temperature for best taste.

2.7. Processing and distribution of frozen food:

Many vegetables, meat, fish and poultry are frozen to sustain the taste, which nearly duplicates that of the fresh product. Freezing retains the sensory qualities of colour, texture and taste apart from nutritional qualities. The refrigeration systems for frozen food applications are very liberally designed, since the food items are frozen in shortest period of time. The sharp freezing with temperature often below –30oC, is done so that the ice crystals formed during freezing do not get sufficient time to grow and remain small and do not pierce the cell boundaries and damage them.Ready-to-eat frozen foods, packed dinners and bakery items are also frozen by this method and stored at temperatures of –25 to -20oC for distribution to retail stores during peak demands or off-season demands.

Vegetables in this list are beans, corn, peas, carrots, cauliflower and many others. Most of these are blanched before freezing. There are various processes of freezing. Blast freezers give a blast of high velocity air at – 30oC on the food container. In contact freezing, the food is placed between metal plates and metal surfaces that are cooled to −30oC or lower. Immersion freezing involves immersion of food in low temperature brine. Individual quick freezing (IQF) is done by chilled air at very high velocities like 5-10m/s that keeps the small vegetable particles or shrimp pieces floating in air without clumping, so that maximum area is available for heat transfer to individual particles. The

frozen particles can be easily packaged and transported. The refrigeration capacities in all the freezers are very large since freezing of large quantities is done in a very short time. Liquid nitrogen and carbon dioxide are also used for freezing.

Of late supermarket refrigeration is gaining popularity all over the world. At present this constitutes the largest sector of refrigeration in developed countries. In a typical supermarket a large variety of products are stored and displayed for sale. Since a wide variety of products are stored, the required storage conditions vary widely. Refrigeration at temperatures greater than 0oC and less than 0oC is required, as both frozen and fresh food products are normally stored in the same supermarket. Following figure shows the photograph of a section of a typical supermarket. Refrigeration systems used for supermarkets have to be highly reliable due to the considerable value of the highly perishable products. To ensure proper refrigeration of all the stored products, a large of refrigerant tubing is used, leading to large refrigerant inventory.

|

| Section of a supermarket with refrigerated display cases |

3. Applications of refrigeration in chemical and process industries

The industries like petroleum refineries, petrochemical plants and paper pulp industries etc. require very large cooling capacities. The requirement of each industry-process wise and equipment-wise is different hence refrigeration system has to be customized and optimized for individual application. The main applications of refrigeration in chemical and process industries involve the following categories.

3.1. Separation of gases:

In petrochemical plant, temperatures as low as –150oC with refrigeration capacities as high as 10,000 Tons of Refrigeration (TR) are used for separation of gases by fractional distillation. Some gases condense readily at lower temperatures from the mixtures of hydrocarbon. Propane is used as refrigerant in many of these plants.

3.2. Condensation of Gases:

some gases that are produced synthetically, are condensed to liquid state by cooling, so that these can be easily stored and transported in liquid state. For example, in synthetic ammonia plant, ammonia is condensed at –10 to 10oC before filling in the cylinders, storage and shipment. This low temperature requires refrigeration.

3.3. Dehumidification of Air:

Low humidity air is required in many pharmaceutical industries. It is also required for air liquefaction plants. This is also required to prevent static electricity and prevents short circuits in places where high voltages are used. The air is cooled below its dew point temperature, so that some water vapour condenses out and the air gets dehumidified.

3.4. Solidification of Solute:

One of the processes of separation of a substance or pollutant or impurity from liquid mixture is by its solidification at low temperature. Lubricating oil is dewaxed in petroleum industry bycooling it below –25oC. Wax solidifies at about –25oC.

3.5. Storage as liquid at low pressure:

Liquid occupies less space than gases. Most of the refrigerants are stored at high pressure. This pressure is usually their saturation pressure at atmospheric temperature. For some gases, saturation pressure at room temperature is very high hence these are stored at relatively low pressure and low temperature. For example natural gas is stored at 0.7 bar gauge pressure and –130oC. Heat gain by the cylinder walls leads to boiling of some gas, which is compressed, cooled and expanded back to 0.7 bar gauge.

3.6. Removal of Heat of Reaction:

In many chemical reactions, efficiency is better if the reaction occurs below room temperature. This requires refrigeration. If these reactions are exothermic in nature, then more refrigeration capacities are required. Production of viscose rayon, cellular acetate and synthetic rubber are some of the examples. Fermentation is also one of the examples of this.

3.7. Cooling for preservation:

Many compounds decompose at room temperature or these evaporate at a very fast rate. Certain drugs, explosives and natural rubber can be stored for long periods at lower temperatures.

3.8. Recovery of Solvents:

In many chemical processes solvents are used, which usually evaporate after reaction. These can be recovered by condensation at low temperature by refrigeration system. Some of the examples are acetone in film manufacture and carbon tetrachloride in textile production.

4. Special applications of refrigeration

In this category we consider applications other than chemical uses. These are in

manufacturing processes, applications in medicine, construction units etc.

4.1. Cold Treatment of Metals:

The dimensions of precision parts and gauge blocks can be stabilized by soaking the product at temperature around – 90oC. The hardness and wear resistance of carburized steel can be increased by this process. Keeping the cutting tool at –100oC for 15 minutes can also increase the life of cutting tool. In deep drawing process the ductility of metal increases at low temperature. Mercury patterns frozen by refrigeration can be used for precision casting.

4.2. Medical:

Blood plasma and antibiotics are manufactured by freeze-drying process where water is made to sublime at low pressure and low temperature. This does not affect the tissues of blood. Centrifuges refrigerated at –10oC, are used in the manufacture of drugs. Localized refrigeration by liquid nitrogen can be used as anesthesia also.

4.3. Ice Skating Rinks:

Due to the advent of artificial refrigeration, sports like ice hockey and skating do not have to depend upon freezing weather. These can be played in indoor stadium where water is frozen into ice on the floor. Refrigerant or brine carrying pipes are embedded below the floor, which cools and freezes the water to ice over the floor.

4.4. Construction:

Setting of concrete is an exothermic process. If the heat of setting is not removed the concrete will expand and produce cracks in the structure. Concrete may be cooled by cooling sand, gravel and water before mixing them or by passing chilled water through the pipes embedded in the concrete.Another application is to freeze the wet soil by refrigeration to facilitate its excavation.

4.5. Desalination of Water:

In some countries fresh water is scarce and seawater is desalinated to obtain fresh water. Solar energy is used in some cases for desalination. An alternative is to freeze the seawater. The ice thus formed will be relatively free of salt. The ice can be separated and thawed to obtain fresh water.

4.6. Ice Manufacture:

This was the classical application of refrigeration. Ice was manufactured in plants by dipping water containers in chilled brine and it used to take about 36 hours to freeze all the water in cans into ice. The ice thus formed was stored in ice warehouses. Now that small freezers and icemakers are available. Hotels and restaurants make their own ice, in a hygienic manner. Household refrigerators also have the facility to make ice in small quantities. The use of ice warehouses is dwindling because of this reason. Coastal areas still have ice plants where it is used for transport of iced fish.

Refrigeration systems are also required in remote and rural areas for a wide variety of applications such as storage of milk, vegetables, fruits, food grains etc., and also for storage of vaccines etc. in health centers. One typical problem with many of the rural and remote areas is the continuous availability of electricity. Since space is not constraint, and most of these areas in tropical countries are blessed with alternate energy sources such as solar energy, biomass etc., it is preferable to use these clean and renewable energy sources in these areas. Thermal energy driven absorption systems have been used in some instances. Vapour compression systems that run on photo-voltaic (PV) cells have also been developed for small applications. Figure 3.5 shows the schematic of solar PV cell driven vapour compression refrigeration system for vaccine storage.

|

| Solar energy driven refrigeration system for vaccine storage |

0 Comments

Please do not enter any spam link in comment box