Pipes are the most dedicate component in any process

plant. They are also the busiest entities. They are subjected to almost all kid

of loads – intentional/unintentional. It is very important to take note of all

potential loads that the piping system would encounter during operation as well

as during other stages in the life cycle of a process plant.

Ignoring any such load while designing, erection, hydro

testing, start-up, shutdown, normal operation, maintenance, etc can lead to an

inadequate design & engineering of the piping system.

The step involved in stress analysis

The approximate step involved in

stress analysis can be listed below.

- Identify potential loads that would come onto the pipe or piping system during the entire life.

- Relate each of these loads to the stress and strains that would be developed in the crystal grain of MOC of the piping system.

- Decide the worst three-dimensional stress states that MOC can withstand without failure.

- Get the Cumulative effect of all the potential loads on the 3D stress scenario in the piping system under consideration.

- Alter the piping system design to ensure that, the stress pattern is within the failure limit.

The Goal of analysis and qualification of the piping

system is to provide safe design through the erection, hydro testing, start-up,

shutdown, normal operation, maintenance, etc. A piping designer would have a

number of alternatives to choose from giving the most suitable & economical

solution.

|

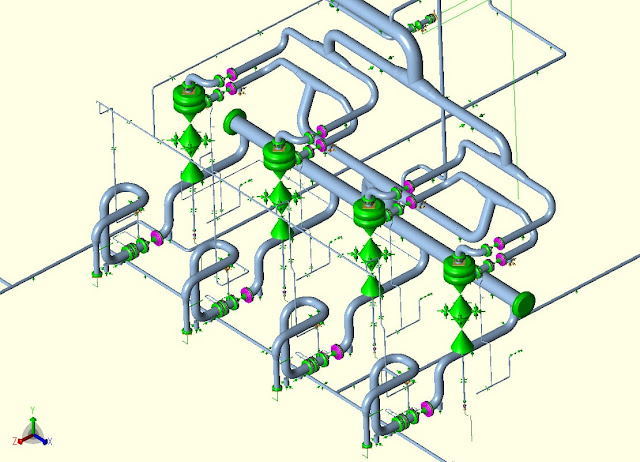

| Pipe Stress work process diagram. |

The objective of Stress Analysis

The objective of piping stress analysis is to ensure safety

against the failure of the piping system by verifying the structural integrity

against the loading condition, both external and internal, expected to occur

during the lifetime of the system in the plant. Thus, the Objective of the Stress analysis could be listed below.

- Ensure that, the stresses in the piping components in the system are within the limits.

- Limiting the sagging of the piping system within allowable limits

- Directing the line movements so as protect sensitive equipment against overloading

- Locating supports, guides, anchors, compressor hold downs, and hanger rods

- Resisting pipe system to collapse in case of earthquake, wind or shock loadings.

- Providing pre-spring, cold spring, clearance required for line expansion, and additional line flexibility.

- Solve dynamic problems developed due to mechanical vibration, acoustic vibration, fluid hammer, pulsation, relief valve, etc.

- Transmitting and handling stress sketches in complete compliance with procedures outlined in Piping Engineering Practices.

- Solve the problem associated due to higher or lower operating temperature such as

·

Displacement stress range

·

Nozzle loading on connecting

equipment.

·

Pipe Displacements

·

Load & Moments on supporting

structures.

Basically, Piping stress analysis is a discipline that is

highly interrelated with the piping layout and support design. The layout of

the piping system should be performed with the requirement of piping stress

& pipe support in mind. i.e.

- Sufficient flexibility for thermal expansion.

- Proper pipe routing so that simple & economical supports can be constructed.

- Piping material & section properties commensurate with the intended services, temperature, pressure & anticipated loading.

- If necessary, the layout solution should be iterated until a satisfactory balance between stress & layout efficiency is achieved.

- Once the piping layout is finalized, the piping support system must be determined.

- Possible support location & type must be iterated until all stress requirements are satisfied & other piping allowable are meet.

- Piping support is then designed base on the selected location and type and the applied loads.

Basically, Piping Designer is not responsible for the

flexibility calculations nor the validity of such calculations made by the

Stress Engineer. Designer is responsible for any calculations or flexibility

analysis that was undertaken and resolved without Stress Supervisor's approval

Causes of pipe stress

The two common causes of pipe stress are weight and thermal

loads which cause loads on equipment nozzles.

1.Weight

Weight causes the pipe to sag, which puts stress into the piping

material

and forces onto equipment nozzle. It includes the weight of the pipe, the weight of the insulation, the weight of valves, instruments, etc.

2.Thermal

When the temperature of the pipe is higher the size of the pipe

increases which causes the nozzle loads to increase and the nozzle loads are

further increased when the supports restrain the pipe from moving. Thus improperly stress the analyzed system will cause very high loads on connecting equipment nozzles.

3.Occasional Loads

The other causes of the pipe stress are the occasional loads

caused due to Wind, earthquakes, dynamic loads due to equipment operation like

Reciprocating Compressor, Pilot safety valve reaction force, Slug flow, etc.

Governing Codes and Standards for Stress Analysis

Codes and Standards specify minimum requirements for safe

design and construction (i. e. provides material, design, fabrication,

installation and inspection requirements.)

Following are the codes and standards used for Refinery

Piping:

·

ASME B31.3: Process piping Code

·

ASME B31.1: Power Piping Code

·

Centrifugal Pumps: API 610

·

Positive Displacement Pumps: API 676

·

Centrifugal Compressors: API 617

·

Reciprocating Compressors: API 618

·

Steam Turbines: NEMA SM23/ API 612

·

Air Cooled Heat Exchanger: API 661

·

Fired Heaters: API 560

·

Flat Bottom Welded Storage Tanks: API

650

·

Heat Exchangers: TEMA/ Vendor

Specific.

·

Vessel/Column: Vendor Specific

3 Comments

Thanks for sharing the best information and suggestions, I love your content, and they are very nice and very useful to us. If you are looking for the best a335 p22, then visit Fastwell. I appreciate the work you have put into this.

ReplyDeleteI agree with a lot of the points you made in this article. If you are looking for the alloy steel pipe, then visit aesteiron. I love your content, they are very nice and very useful to us and this text is worth everyone’s attention.

ReplyDeleteReally helpful down to the ground, happy to read such a useful post. I got a lot of information through it and I will surely keep it in my mind. Keep sharing. If you are looking for some useful data and information regarding Grade 10.9 Bolts then visit VIHA STEEL & FORGING.

ReplyDeletePlease do not enter any spam link in comment box