Introduction

The primary objective of study properties

of piping materials is to provide an piping engineer with tools of analyzing and designing piping components. To determine the

suitability of a material under the given loading conditions requires the

knowledge of various types of stresses incurring on the components as well as

the mechanical properties of the materials. No material can possess all the desired properties in one material. Depending upon the requirements, sometimes a compromise may have to be made while choosing a particular material for a

part of a machine and Piping. This blog describes some of the properties most commonly

to determine these properties.

The main properties of materials are as follows:

Ductility

It is the property of a material by

virtue of which it can be drawn into wires under the action of tensile force. A

ductile material must have a high degree of plasticity and strength so that

large deformations can take place without failure or rupture of the material.

In ductile exhibits a certain amount of elasticity along with a high degree of

plasticity.

Brittleness

It is opposite to ductility, i.e., when

a material. Cannot be drawn out by tension to smaller sections. A brittle fails

instantly under the load with out exhibiting any significant deformation.

Examples of brittle materials are cast iron, concrete, glass, stone, etc.

Malleability

This property of a material allows it to

expand in all directions without rupture. A malleable material has to be highly

plastic, though it may not possess high strength. This property is of great use

in processes such as forging, hot rolling, etc.

Hardness

The resistance of a material to

indentation including scratching or surface abrasion is termed as hardness.

Strength

It may be defined as the capability of a

material to withstand load. It is obtained by divided the load by area. The

ultimate strength of material is the load. Required to cause fracture divided

by the area of the test specimen.

Toughness

It is the capacity of a structure to

withstand an impact load, i.e.., the capacity to absorb without fracture. It

depends upon the ductility of a material and its ultimate strength. toughness

is represented by the area under the stress- strain diagram and is the energy

per unit volume required to cause the material to rupture. This property is

highly desirable in components subject to shock or cyclic loading. A general

test for toughness is the bend test in which the capability of a material is

tested for angular bending.

Fatigue

When loading are repeated thousands or

millions of times, rupture occurs at a stress much below the static breaking

strength. This phenomenon is known as fatigue. Consideration of fatigue is an

integral part of design if the structural or machine components are subjected to

fluctuating or repeated loads.

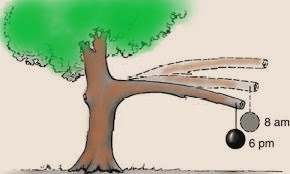

Creep

If the stress in a material exceeds the

yield point, the strain caused in the material by the application of load does

not disappear totally on the removal of load. The plastic deformation caused to

the material is known as creep. At high temperatures, the strain due to creep

is quite appreciable.

More detail about the creep is already covered

in article; Time Dependent Stresses: Creep

0 Comments

Please do not enter any spam link in comment box