Type of Discontinuities

Discussing can be divided into three general categories: Inherent, Processing, and Service.

A. Inherent Discontinuities

Inherent Discontinuities are usually formed when the metal is molten. Inherent wrought discontinuities relate to the melting and solidification of the original ingot before it is formed into slabs blooms, and billets.

Inherent cast

discontinuities relate to the melting, casting, and solidification of a cast

article. Usually caused by inherent variables such as inadequate feeding,

gating, excessive pouring temperature, and entrapped gases.

B. Processing Discontinuities

Processing

discontinuities are usually related to the various manufacturing processes such

as machining. Forming, extruding, rolling, welding, heat treating, and plating.

C. Service Discontinuities

Service discontinuities are related to the various service conditions such as stress, corrosion, fatigue, and erosion.

During the manufacturing process, many

discontinuities that were subsurface (and not detectable by magnetic particle

inspection) will be made open to the surface by machining, grinding, etc.

Remember that

discontinuities are not necessarily defects.

Any

indication that is found by the inspector is called a discontinuity until it

can be identified and evaluated as the effect it will have on the service of

the part.

The greatest aid in interpretations is a knowledge of what is likely to be present in any given instance. Knowing the history of a part, what it is made of and what processes it has been through all form important considerations.

Type of Indication

Every

magnetic particle pattern produced is due to some magnetic disturbance set up

in a leakage field the inspector must be able to determine whether there is a

serious crack, or some insignificant or unimportant non-relevant indication.

Surface

indications produce sharp, distinct, clean-cut, and tightly held indication

patterns. Subsurface indications tend to produce indications which are less

distinct, forming diffused or fuzzy patterns.

Non-relevant Indications

This is a group of non-relevant magnetic disturbances not due to

discontinuities or actual breaks in the metal a common non-relevant indication

could be caused by, a constriction in a metal through which lines of force must

pass, such as the shaft with a key way shown below.

Non-relevant

indications can be caused by the following:

- Excessive magnetizing current.

- Structural design of the article.

- Variances of permeability within the article.

Over-magnetization could cause a non-relevant indication due to the leakage field attracting particles as shown below.

Excessive magnetization can also cause non-relevant indications on a simple square object as shown on the circularly magnetized part below.

Abrupt changes

of section thickness of a longitudinally magnetized the part will causes flux leakages where the line of force leave or enter the part, causing

non-relevant indications.

Permeability differences in the part can also cause non-relevant indications. Cold working a metal can change the permeability.

Example: Bending and Straightening a nail

will cause the metal to become hard at the point of bending. When the nail is

magnetized there will be a flux leakage where the permeability is changed. (see

below)

A non-relevant indication would also appear across the shank of a cold chisel where the heat -treated portion ends and the soft shank begins. (see below)

- They can be identified by a fuzzy, rather than a sharp, indication.

- They are usually associated with some feature of construction like a keyway or sharp corner.

- They are usually uniform in direction and size.

False Indication

False

indication are caused when particles are accumulated and held mechanically or

by gravity. If the part has a rough surface this may cause false indications.

Inherent Discontinuities

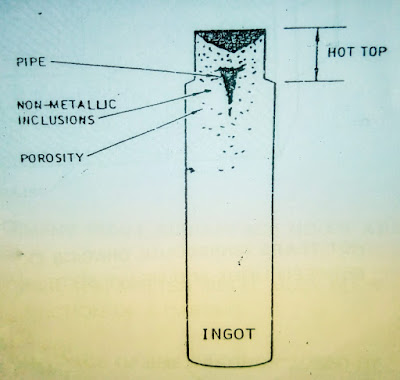

Inherent Discontinuities relate to the original melting and solidification of the metal in the ingot or in a casting. Typical discontinuities found in the ingot are inclusions, blowholes, pipe, and segregation.

- Nonmetallic inclusions such as slag, oxides, and sulphides are present in the original ingot.

- Blowholes (porosity) are formed by gas which is insoluble in the molten metal and is trapped when the metal solidifies.

- Pipe is a discontinuity in the center shrinkage during solidification.

- Segregation occur when the distribution of the various elements is not uniform throughout the ingot. This condition is called “banding” and is not usually significant.

When an ingot is further processed into slabs’ blooms, and billets, it is possible for the above discontinuities to change size and shape. The discontinuities after rolling and forming are called lamination, stringers, or seams depending on the type of processing and the original type of discontinuity.

The “Hot Top” is usually cropped off to remove most of the discontinuities, before the ingot is further processed.

Typical Inherent Discontinuities found in castings are Cold shuts, Hot tears, shrinkage cavities, micro shrinkage, blowholes, and porosity.

A Cold Shut is caused when molten metal is poured over solidified metal as

shown below:

Hot tears (shrinkage cracks) occur when there is unequal shrinkage between light and heavy sections as shown below:

Shrinkage

cavities are usually caused by lack of enough molten metal to fill the space created

by shrinkage, similar to pipe in the ingot.

Micro shrinkage usually appears as many small subsurface holes at the gate of the casting. Micro shrinkage can also occur when the molten metal must flow from a thin section into a thicker section of a casting.

Blow holes are small holes at the surface of the casting caused by gas which comes from the mold itself. Many molds are made of sand and when molten metal comes into contact with the mold. The water in the sand is released as steam.

Porosity is caused by entrapped gas. Porosity is usually subsurface but can occur on the surface depending on the design of the mold.

Processing Discontinuities

Processing discontinuities are those found or produced by forming or fabrication operations including rolling, forging, welding, machining grinding, and heat treating.

As a billet is flattened and spread out,

nonmetallic inclusions may cause a lamination. Pipe and porosity could also

cause lamination in the same manner as shown below

As a billet is rolled into bar stock, nonmetallic inclusions are squeezed out into longer and thinner discontinuities called stringers.

Welding discontinuities

The following are types of processing discontinuities.

Forging Discontinuities

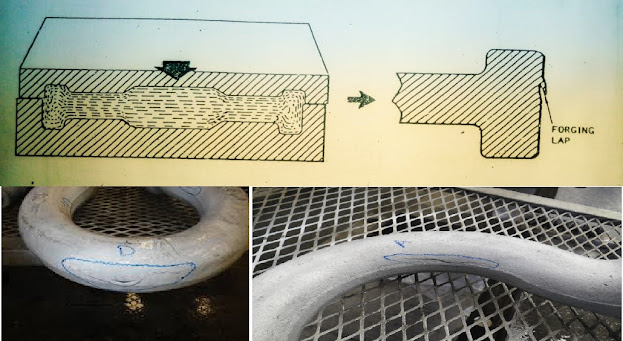

Forging discontinuities occur when metal is hammered or pressed into shape, usually while the metal is very hot. A forged part gains strength due to the grain flow taking the shape of the die. This process is shown below.

A Forging Lap is caused by folding of metal on the surface of the forging, usually when same of the for forging metal is squeezed out between the two dies.

A Forging Burst is a rupture caused by forging at improper temperatures. Bursts may be either internal or open to the surface as shown below.

Grinding cracks are a processing Type discontinuity caused by stresses which are built up from excess heat created between grinding wheel and metal.

Grinding Cracks will usually occur at right angles to the rotation of the grinding Wheel.

Heat Treating Cracks are often caused by the stresses built up during heating and cooling.

Unequal cooling between light and heavy sections may cause heat treat cracks.

Heat treat cracks have no specific direction and usually start at sharp corners

which act as stress concentration points.

Service Discontinuities

Service discontinuities are probably the most important types to considered extremely. Article which may develop defect due to Metal Fatigue are considered Extremely Critical and demand close attention.

Fatigue cracks are service- type discontinuities that are usually open to the surface where they start from concentration points.

Fatigue cracks are possible only after the part is placed into service, but may be the result of porosity, inclusions, or other discontinuities in a highly stressed metal part.

Preservation

of Indications

It is often desirable to preserve magnetic particle indications for future reference. There are several methods used to accomplish this purpose.

- Lacquer Technique requires the indication to be sprayed with a clear lacquer and later photographed.

- Direct Photography is used to record the indication immediately after performing the test.

- Magnetic Rubber uses a process where the magnetic particles are in solution with a liquid rubber. The rubber is allowed to harden on the part after the magnetic field has arranged the magnetic particles.

- Transparent Tape Transfer is commonly used to lift the indication from the part. The tape can be photographed or placed directly into a permanent record book.

0 Comments

Please do not enter any spam link in comment box