Alternating Current (AC) is the most widely use for conducting magnetic particle testing. AC can be readily converted to the low voltages used in magnetic particle inspection using transformers. AC has little penetrating power and provides the best detection of surface discontinuities. It is not effective for subsurface. Since AC is continuously reversing direction. The magnetic field has a tendency to agitate or make the iron particles more mobile.This causes the iron particles to be more responsive to the flux leakage.Current reversal is illustrated below.

Direct

current (DC)-single phase ac can be rectified to produce half-wave alternating current (HWAC) commonly

called half-wave direct current (HWDC).

HWDC means that the reverse polarity or negative portion of the sine curve is eliminated as below.

With HWDC there are intervals of individual pulses of direct current and also intervals when no current is flowing.

Hysteresis

loop:

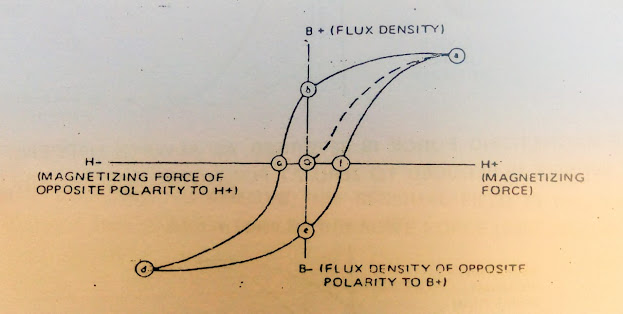

The permeability of a material can be determined by increasing the magnetizing force (electric current strength) until the material reaches its saturation point. Each type of material has a point of maximum flux density (saturation). if we place a piece of steel in a coil. Through which alternating current is flowing. We can plot the relation between magnetizing current “H” and the flux density “B” the result is a hysteresis loop as shown below.

At each increase of the force “H” there is an increase in flux density “B” until the Saturation Point is reached. The dashed line above (points o-a) shows the maximum flux density and is often referred to as the virgin curve. As the magnetic force is increased. The flux in the material in creases quit rapidly at first, then more slowly until it reaches a point beyond which any increase in the magnetizing force does not increase the flux density (point A).

As the magnetizing force is reduced to zero (from point a to b), the flux density slowly drops until the magnetizing force (current) is zero (see below). The ability of the steel to retain a certain amount of residual magnetism is called retentivity, as shown between points o and b.

When the magnetizing force is reversed, as always happens with ac, the flux density is reduced to zero at point c as shown below.

Coercive force is the reverse magnetizing force required to remove residual magnetism from the material as shown above.

Hardened steel would require a stronger reverse magnetizing force to remove the residual magnetism. As the reverse magnetizing force is increased beyond point "c", the flux density increases to the saturation point in the reverse direction shown in point "d" below.

Point e below shows the residual magnetic field in the reverse direction.

The force required to remove this residual field is shown between points o and f and is again called coercive force (see below).

The hysteresis loop is completed as the magnetizing force is again increased to a maximum flux density at point a.

As shown on the previous, a hysteresis loop is formed with every complete cycle of 60 cps current. A hysteresis loop could also be used to describe the magnetization or demagnetization with dc where the current is either manually or automatically reversed between straight (+) polarity and reverse (-) polarity.

A wide hysteresis loop indicates a material that is difficult to magnetize (one with a high reluctance). The hysteresis loop gets its name from the lag between the applied magnetizing force and the actual flux density in the part. This lag is shown between points o and f below.

The distance between points o and f above will depend on the coercive force needed to overcome the reluctance of the steel.

A hard steel

would have the following qualities and would produce a wide hysteresis loop.

1.low

permeability- hard to magnetize.

2.High

retentivity- retains a strong residual magnetic field.

3.High

coercive force-requires a high reverse magnetizing force to remove the residual

magnetism.

4.High

reluctance- high resistance to magnetizing force.

5.High residual magnetism- retains a strong residual magnetic field.

A thin hysteresis

loop indicates a material of low retentivity.

The loop below shows the qualities of a soft material such as low carbon steel. The coercive force is low because the material retains only a weak residual magnetic field.

A soft or low carbon steel would have the following qualities:

1.High

permeability- easy to magnetize.

2.Low retentivity-retains

a weak residual magnetic field.

3.Low coercive

force- requires a low reverse magnetizing force to remove the residual

magnetism.

4.Low

reluctance- low resistance to magnetizing force.

5.Low

residual magnetism- retains a weak residual magnetic field.

Few more piping resources...

0 Comments

Please do not enter any spam link in comment box